POWER SUPPLY

As sounds, power supply gives power to all electronic circuits and if we consider it in a broader way, power supply is essential for all the activities happening around us, even we the human being need power to perform our day to day life. So, good, clean and regular power is must for all activities including electronic equipments.

In this post, I will emphasize on how to design a good simple power supply. Here under in fig-1 block diagram is given mentioning the essential elements of a power supply.

A.C. mains 220/230 V (in some countries 110 V) is first stepped down to a required level, rectified, filtered and then regulated (if required). Most of the circuits require a combination of unregulated and regulated supply out puts. Below in Fig-2 a simple zener regulated power supply is given. This power supply gives 12 volts at 50 M. amp. It is suitable for reference voltages or an op-amp.

If higher current is a requirement, power supply shown in Fig-3 below is more suitable. In this supply transistor 2N3055 is used as a series pass element. This supply can deliver upto 500 M. Amp. which is suitable for most of the circuits. Proper size heat sink is necessary for the transistor to safeguard from undesirable heating. 80 MM X 40 MM X 3 MM thick aluminium heat sink is sufficient. This supply does not have over load or short circuit protection, therefore a 500 M. Amp. fuse may be added between power supply and the load. To obtain adject 12 volts diode D5 has to be inserted between anode of zener ZD1 and ground as shown in the figure as the base emitter junction of transistor Q1 drop 0.6 volts.

While designing a power supply, the first component is transformer.

Transformer must be capable to handle the current which it has to deliver continuously. An ideal consideration is the transformer should have double the capacity of required load, if it has to supply continuous current and 1.5 times the capacity of required current if it has intermittent load, just as an audio amplifier. I shall discuss how to design a transformer separately. Here I give two ideas to test a transformer.

a) Put a dummy load, preferably rheostat across the secondry winding of transformer under test. Connect primary winding to A.C. mains and adjust the current to 25 % of its capacity. Now set the mains voltage to 275 volts through variac ( for 220 volts transformer) and leave it for at least one hour. The transformer should not heat up. It should be just warm 30 -32 degree celsius.

b) Do not connect any load to secondry winding, connect primary winding to A.C. source and set the input voltage to 300 Volts. Leave it for one hour. The temperature of transformer should remain at room temperature.

Above in Fig-4, darlington pair of transistors Q1 and Q2 used to enhance the current capacity of power supply. A larger heat sink is required to cool down the series pass transistor Q1. An additional transistor Q3 with heat sink may be added to further enhance the current capacity of power supply, when single transistor is not able to pass sufficient current required by the load, darlington pair is a good solution to resolve the issue. Diodes D5 & D6 in series with zener diode ZD1 be added to obtain adject 12 volts, since Q1, Q2 together drop 1.2 volts through base emitter junction.

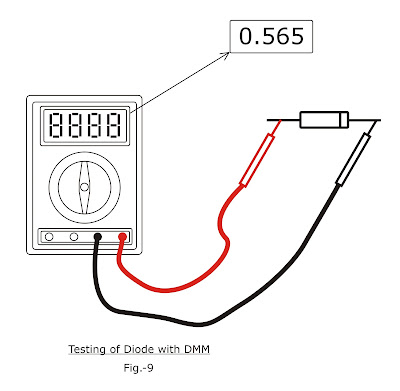

Stepped down A C is to be rectified by a rectifier. Two points are to be kept in mind while selecting a rectifier diode, current capacity & the break down voltage. Diode 1N4007 has a current capacity of 1 amp. and break down voltage 1000 volts, hence 1N4007 is suitable for most of the power supplies. For up to 3 amp. supplies 1N5408 (current 3 amp., break down 1000 V) and up to 6 amp. diode 6A4 (current 6 amp., break down 400 V) is suitable.

Filter selection is also very important for a good power supply. Use only best available quality capacitors ( cost doesn't matter). A quite simple consideration for selecting a capacitor is 1000 Mfd. for each one ampere of load i.e. up to 1 amp. 1000 Mfd., 2 amp. 2200 Mfd, 3 amp. 3300 Mfd and so on. For variable load such as audio amplifiers an additional 1000 Mfd. may be added to the capacitor value to maintain voltage at higher volume thus audio quality too.

Voltage regulation is most critical part of any power supply. there are many ways to keep the voltage at constant level under line and load variations.

Besides this, over load and short circuit protection also has equal importance.

As sounds, power supply gives power to all electronic circuits and if we consider it in a broader way, power supply is essential for all the activities happening around us, even we the human being need power to perform our day to day life. So, good, clean and regular power is must for all activities including electronic equipments.

In this post, I will emphasize on how to design a good simple power supply. Here under in fig-1 block diagram is given mentioning the essential elements of a power supply.

A.C. mains 220/230 V (in some countries 110 V) is first stepped down to a required level, rectified, filtered and then regulated (if required). Most of the circuits require a combination of unregulated and regulated supply out puts. Below in Fig-2 a simple zener regulated power supply is given. This power supply gives 12 volts at 50 M. amp. It is suitable for reference voltages or an op-amp.

If higher current is a requirement, power supply shown in Fig-3 below is more suitable. In this supply transistor 2N3055 is used as a series pass element. This supply can deliver upto 500 M. Amp. which is suitable for most of the circuits. Proper size heat sink is necessary for the transistor to safeguard from undesirable heating. 80 MM X 40 MM X 3 MM thick aluminium heat sink is sufficient. This supply does not have over load or short circuit protection, therefore a 500 M. Amp. fuse may be added between power supply and the load. To obtain adject 12 volts diode D5 has to be inserted between anode of zener ZD1 and ground as shown in the figure as the base emitter junction of transistor Q1 drop 0.6 volts.

While designing a power supply, the first component is transformer.

Transformer must be capable to handle the current which it has to deliver continuously. An ideal consideration is the transformer should have double the capacity of required load, if it has to supply continuous current and 1.5 times the capacity of required current if it has intermittent load, just as an audio amplifier. I shall discuss how to design a transformer separately. Here I give two ideas to test a transformer.

a) Put a dummy load, preferably rheostat across the secondry winding of transformer under test. Connect primary winding to A.C. mains and adjust the current to 25 % of its capacity. Now set the mains voltage to 275 volts through variac ( for 220 volts transformer) and leave it for at least one hour. The transformer should not heat up. It should be just warm 30 -32 degree celsius.

b) Do not connect any load to secondry winding, connect primary winding to A.C. source and set the input voltage to 300 Volts. Leave it for one hour. The temperature of transformer should remain at room temperature.

Above in Fig-4, darlington pair of transistors Q1 and Q2 used to enhance the current capacity of power supply. A larger heat sink is required to cool down the series pass transistor Q1. An additional transistor Q3 with heat sink may be added to further enhance the current capacity of power supply, when single transistor is not able to pass sufficient current required by the load, darlington pair is a good solution to resolve the issue. Diodes D5 & D6 in series with zener diode ZD1 be added to obtain adject 12 volts, since Q1, Q2 together drop 1.2 volts through base emitter junction.

Stepped down A C is to be rectified by a rectifier. Two points are to be kept in mind while selecting a rectifier diode, current capacity & the break down voltage. Diode 1N4007 has a current capacity of 1 amp. and break down voltage 1000 volts, hence 1N4007 is suitable for most of the power supplies. For up to 3 amp. supplies 1N5408 (current 3 amp., break down 1000 V) and up to 6 amp. diode 6A4 (current 6 amp., break down 400 V) is suitable.

Filter selection is also very important for a good power supply. Use only best available quality capacitors ( cost doesn't matter). A quite simple consideration for selecting a capacitor is 1000 Mfd. for each one ampere of load i.e. up to 1 amp. 1000 Mfd., 2 amp. 2200 Mfd, 3 amp. 3300 Mfd and so on. For variable load such as audio amplifiers an additional 1000 Mfd. may be added to the capacitor value to maintain voltage at higher volume thus audio quality too.

Voltage regulation is most critical part of any power supply. there are many ways to keep the voltage at constant level under line and load variations.

Besides this, over load and short circuit protection also has equal importance.